Page 206 - Catalogue_2025+

P. 206

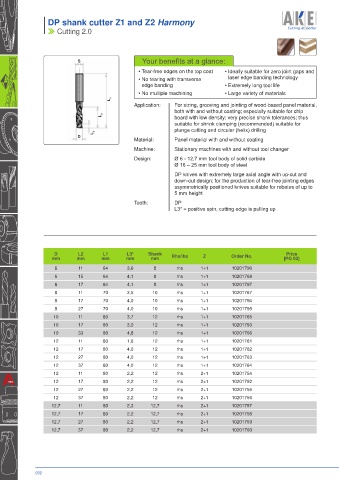

I DP shank cutter Z1 and Z2 Harmony I DP shank cutter Z2 and Z3 Harmony

I Cutting 2.0 I Cutting 2.0

S Your benefits at a glance:

• Tear-free edges on the top coat • Ideally suitable for zero joint gaps and

• No tearing with transverse laser edge banding technology

edge banding • Extremely long tool life

• No multiple machining • Large variety of materials

L 1

Application: For sizing, grooving and jointing of wood-based panel material,

both with and without coating; especially suitable for chip

L 2 board with low density; very precise shank tolerances; thus

suitable for shrink clamping (recommended) suitable for

plunge cutting and circular (helix) drilling

L 3

D

Material: Panel material with and without coating

Machine: Stationary machines with and without tool changer

Design: Ø 6 - 12,7 mm tool body of solid carbide

Ø 16 – 25 mm tool body of steel

DP knives with extremely large axial angle with up-cut and

down-cut design; for the production of tear-free jointing edges

asymmetrically positioned knives suitable for rebates of up to

5 mm height

Tooth: DP

L3* = positive spin, cutting edge is pulling up

D L2 L1 L3* Shank Price

mm mm mm mm mm Rhs/lhs Z Order No. [PG 03]

6 11 64 3,6 8 rhs 1+1 10201796

6 15 64 4,1 8 rhs 1+1 10201768

6 17 64 4,1 8 rhs 1+1 10201797

8 11 70 2,5 10 rhs 1+1 10201767

8 17 70 4,0 10 rhs 1+1 10201794

8 27 70 4,0 10 rhs 1+1 10201795

10 11 80 3,7 12 rhs 1+1 10201765

10 17 80 3,0 12 rhs 1+1 10201793

10 33 80 4,8 12 rhs 1+1 10201766

12 11 80 1,8 12 rhs 1+1 10201761

12 17 80 4,0 12 rhs 1+1 10201762

12 27 80 4,0 12 rhs 1+1 10201763

12 37 80 4,0 12 rhs 1+1 10201764

12 11 80 2,2 12 rhs 2+1 10201754

12 17 80 2,2 12 rhs 2+1 10201792

12 27 80 2,2 12 rhs 2+1 10201755

12 37 80 2,2 12 rhs 2+1 10201756

12,7 11 80 2,3 12,7 rhs 2+1 10201757

12,7 17 80 2,2 12,7 rhs 2+1 10201758

12,7 27 80 2,2 12,7 rhs 2+1 10201759

12,7 37 80 2,2 12,7 rhs 2+1 10201760

202