Page 159 - Catalogue_2025+

P. 159

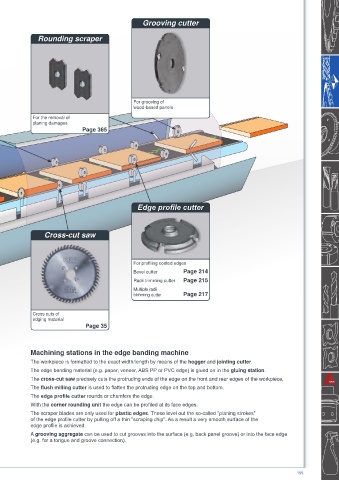

Grooving cutter

Rounding scraper

For grooving of

wood-based panels

For the removal of

planing damages

Page 365

Edge profile cutter

Cross-cut saw

For profiling coated edges

Bevel cutter Page 214

Radii trimming cutter Page 215

Multiple radii

trimming cutter Page 217

Cross cuts of

edging material

Page 35

Machining stations in the edge banding machine

The workpiece is formatted to the exact width/length by means of the hogger and jointing cutter.

The edge banding material (e.g. paper, veneer, ABS PP or PVC edge) is glued on in the gluing station.

The cross-cut saw precisely cuts the protruding ends of the edge on the front and rear edges of the workpiece.

The flush milling cutter is used to flatten the protruding edge on the top and bottom.

The edge profile cutter rounds or chamfers the edge.

With the corner rounding unit the edge can be profiled at its face edges.

The scraper blades are only used for plastic edges. These level out the so-called "planing strokes"

of the edge profile cutter by pulling off a thin "scraping chip". As a result a very smooth surface of the

edge profile is achieved.

A grooving aggregate can be used to cut grooves into the surface (e.g. back panel groove) or into the face edge

(e.g. for a tongue and groove connection).

155